The heat transfer plates have holes at the four corners. Tubes are made from low carbon steel stainless steel titanium Inconel Copper etc.

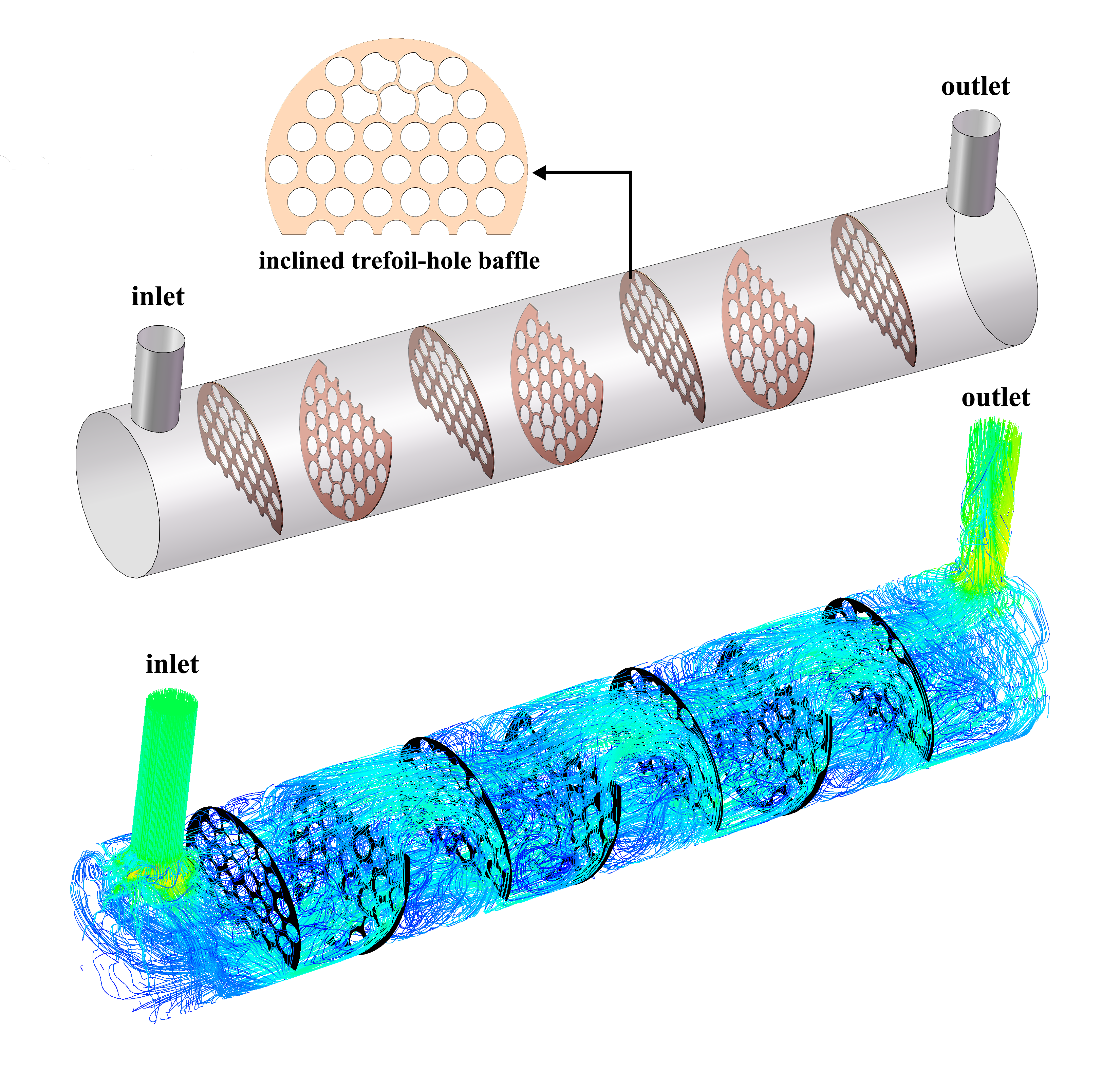

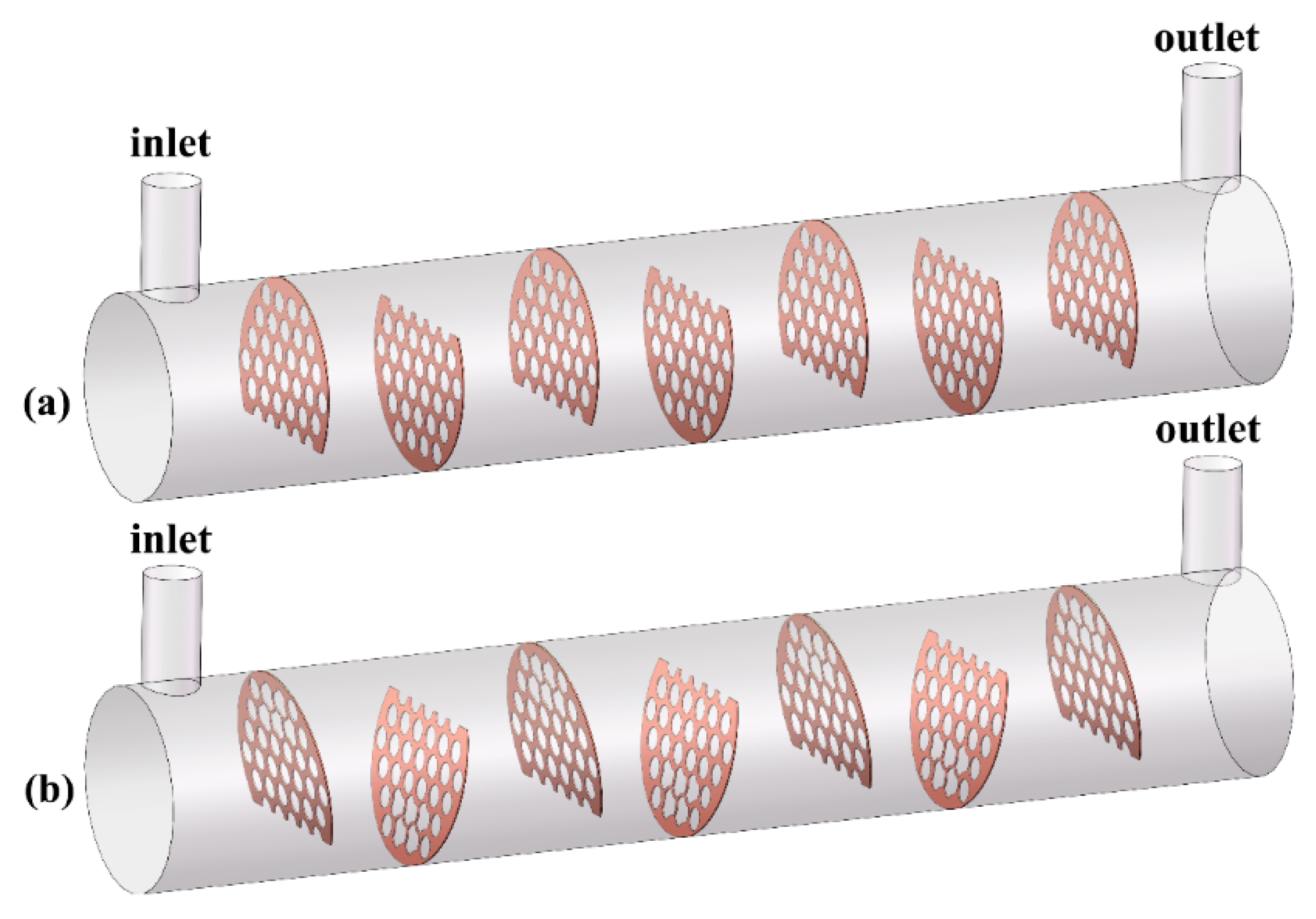

Energies Free Full Text Numerical Investigation And Optimization On Shell Side Performance Of A Shell And Tube Heat Exchanger With Inclined Trefoil Hole Baffles Html

By The Engineering Concepts.

. Tubesheets less than 100 mm thick are generally made from plate material. Learn about the design. API Heat Transfer is a worldwide leader in high-performance heat transfer solutions ready to meet any challenge anywhere around the globe head on.

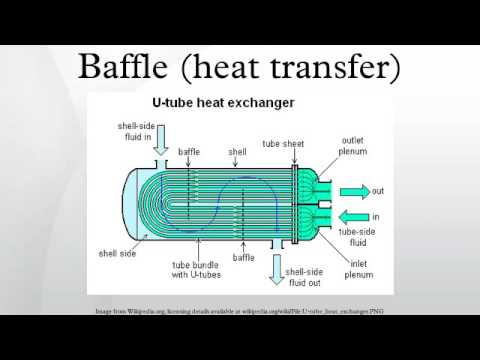

One of the cornerstones of an effective design for a shell-and-tube exchanger is ideal flow on the shellside of the heat exchanger which is largely controlled by the baffle specifications. Baffle is a shell side component of Shell and Tube Heat Exchanger. Baffles are an integral part of the shell and tube heat exchanger design.

The tube bundle is the most important part of a tubular heat exchanger. The baffle pitch and baffle cut are selected during the heat exchanger design to yield the highest fluid velocity and heat transfer rate while respecting the allowable pressure drop. Plateflow uses a combination of chevron-style heat transfer plates sequenced between a frame plate and pressure plate.

Mechanical engineers do extensive work on exchanger design to fully specify the exchanger eg. Shell and tube type heat exchanger with helical baffle 42 Baffle spacing Baffle spacing is the centerline to-centerline distance between adjacent baffles. The normal recommended value of 20 to 25 cut of shell diameter is used in shell and tube heat exchanger design the larger the cut the lower the pressure drop however.

The gasket arrangement of each pair of plates provides two separate. The shell-and-tube heat exchangers with helical baffles consist of the cylinder heat-transfer tubes and baffles. Plate Heat Exchanger A plate heat exchanger contains an amount of thin shaped heat transfer plates bundled together.

Tubes baffles shell size tie rods sealing strips skid bars etc. The pressure drop is decreased by 4 for heat exchanger with 10 baffle inclination angle and by 16 for heat exchanger with 20 baffle inclination compared to 0 baffle inclination heat. But designing heat exchanger might be a challenge.

The vendor receives the. Optimal design of heat exchangers Wilfried Roetzel. Hence a guideline to properly select and sizing is needed.

1 Heat exchangers definition. Standard Xchange designs and manufactures heat exchanger products for the chemical pulp and paper biofuels sugar processing petroleum power generation mining and general industrial. A baffle plate 28 for supporting tubes 16 in a heat exchanger shell 12 comprises a sheet of non-metallic material formed with a plurality of closely spaced cylindrical holes through which.

It needs iteration for manual calculation. 34 Plate baffles vs rod baffle Jie Yang et al have performed modelling and computational estimations for baffle and furthermore the demonstrating methodology is confirmed with. It is used to cool the electronic devices to a fluid medium or liquid coolant.

It is the most vital. 3 rows Baffles are components of shell and tube heat exchangers which are used to support and fix the. Baffle plate with holes to fit around the tubes of a heat exchanger has tubes of a non-uniform cross-section so that an annular contact exists between the plate and the tube at the.

The most familiar example would be the heat sink. The Heat Exchange Design Handbook contains two chapters discussing these factors. The heat sink is a kind of.

Dezhen Chen in Design and Operation of Heat Exchangers and their Networks 2020 5222 Bell-Delaware method In the shell side the. The Helical Baffle improves the performance of the Heat Exchanger over the segmental it gives the better heat transfer rate. Standard tube diameters of 58 inch 34 inch and 1 inch are preferably used to design compact heat.

The tubes generally constitute the most expensive component of the exchanger and are the one most. The shell diameter of heat exchanger is 250 mm and 2500. Baffles are mainly used in indudtrial process vessels or tanks such as.

It is used in some household stoves and in some industrial process vessels tanks such as shell and tube heat exchangers chemical reactors and static mixers. Static mixers agitators chemical reactors heat exchangers. Baffles are flow-directing or obstructing vanes or panels used to direct a flow of liquid or gas.

The Shape Of Three Heat Exchangers A Graphical Model Of Segmental Download Scientific Diagram

Energies Free Full Text Numerical Investigation And Optimization On Shell Side Performance Of A Shell And Tube Heat Exchanger With Inclined Trefoil Hole Baffles Html

Heat Exchanger Baffles Oil And Gas Separator

Nomenclature And Geometrical Aspects Of The Shell And Tube Heat Download Scientific Diagram

Optimizing Shell Side Baffle Spacing Enggcyclopedia

Numerical Simulation Of The Effect Of Baffle Cut And Baffle Spacing On Shell Side Heat Exchanger Performance Using Cfd

0 comments

Post a Comment